Kramer Expanded Glass

In 2013 Kramer Schaumsilikate GmbH invested in building of Russian plant that produces expanded glass granulate - universal thermal insulation filler - using German technology and equipment.

Kramer expanded glass makes products more lightweight and easier to apply. It can significantly improve the performance of your products and cut down expenses in the long run.

The raw material for Kramer Expanded Glass is post-consumer recycled glass.

Kramer Expanded Glass

Expanded glass has a very good thermal and sound insulating properties, it is also resistant to moisture, fire, chemicals and is dimensionally stable even after years without shrinkage and swelling.

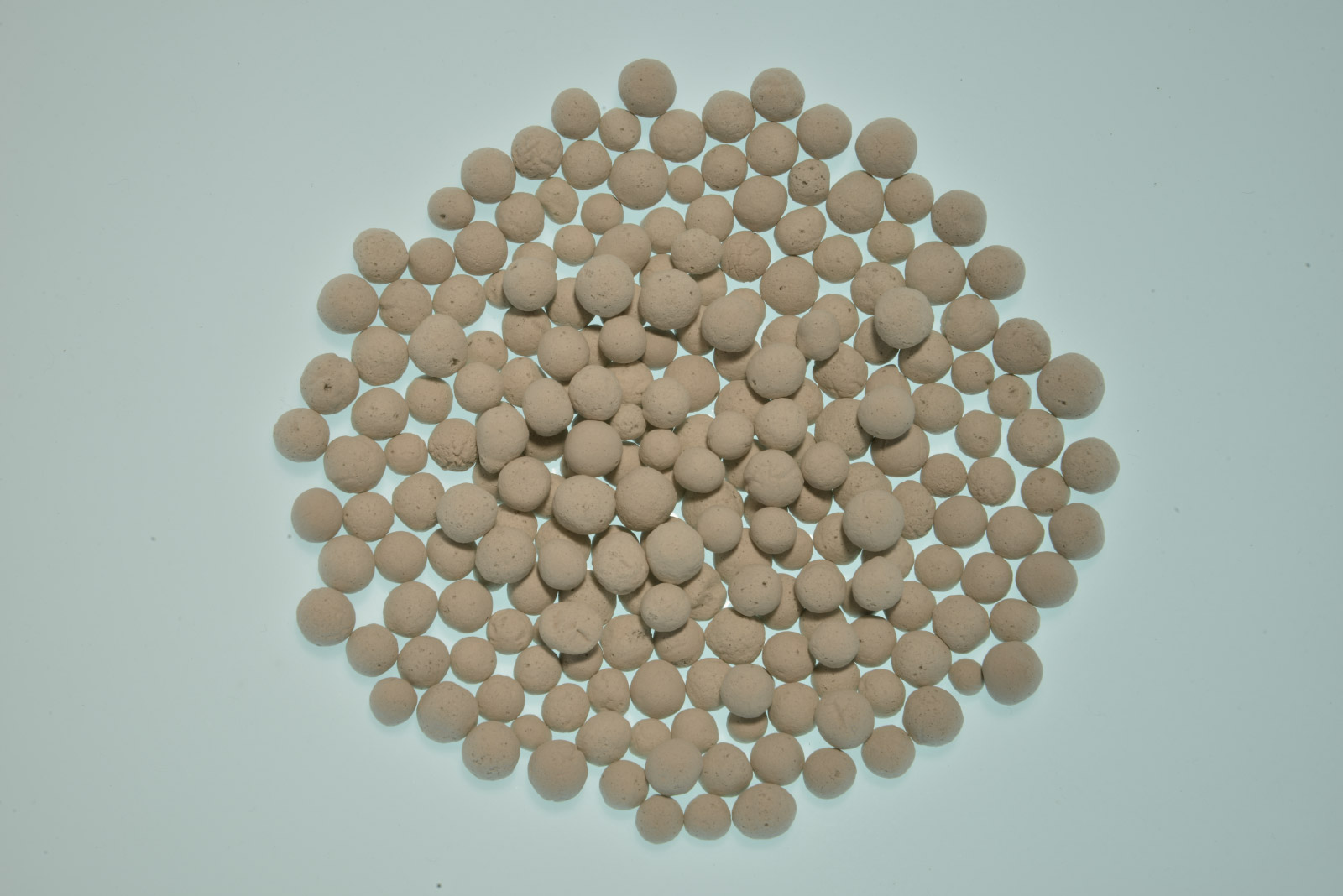

Kramer Expanded Glass is a grey lightweight aggregate with bulk densities starting from 100 kg/m³.

We produce Kramer Expanded Glass in 4 standard grain size:

- ø 1 - 2 mm

- ø 2 - 4 mm

- ø 4 - 8 mm

- ø 8 - 16 mm

Grain size: ø 1 - 2 mm

Bulk Density, kg/m³: 150±30

Compressive Strength, MPa, not less: 0,3

Thermal conductivity, W/m-K, not more: 0,06

Work temp., С°: 500

Grain size: ø 2 - 4 mm

Bulk Density, kg/m³: 130±30

Compressive Strength, MPa, not less: 0,4

Thermal conductivity, W/m-K, not more: 0,06

Work temp., С°: 500

Grain size: ø 4 - 8 mm

Bulk Density, kg/m³: 100±20

Compressive Strength, MPa, not less: 0,3

Thermal conductivity, W/m-K, not more: 0,055

Work temp., С°: 500

Grain size: ø 8 - 16 mm

Bulk Density, kg/m³: 100±20

Compressive Strength, MPa, not less: 0,3

Thermal conductivity, W/m-K, not more: 0,055

Work temp., С°: 500

Main Properties of Kramer Expanded glass granulate

Low density combines withe the high compressive strength;

Excellent thermal insulating and sound absorption properties;

Spherical grain shape;

Color Grey/Cream/White, for any client’s purposes;

100 % mineral;

Fire and heat resistant;

Health- and Environment friendly material: inert, non-toxic, solvent-free, fibre-free, odor-neutral, anti-allergen and radiologically completely safe;

Long-term stability;

Chemical and biological resistance.

The benefits of Kramer Expanded Glass as lightweight aggregate

OPTIMISING PRODUCTS

- due to the low density and spherical shape reduces production costs.

- reduces the use of other materials, such as resins, cellulose ether and other binding materials.

- preserves the rheological properties of the mortar.

- remains stable in the building construction, and during the expected life of the building: it gives no shrinkage and prevents the formation shrinkage cracks.

TECHNOLOGICAL ADVANTAGES

- increases the yield while preserving of the final product’s quality.

- gives the product a more elastic structure that allows it to take more deforming load and enhance stability to attrition.

- improves adhesion and works as an adhesive mortar that is a great advantage for the exterior.

- reduces the water absorption, adjusts the water vapour permeability rate and reduce the risk of efflorescence, cracking and reduces rejects.

ENVIRONMENT AND SAFETY

Kramer Expanded Glass is a non-toxic, odorless, does not emit dust, it doesn’t cause any allergic reactions. It can be recycled as well. With Kramer Expanded Glass lightweight concrete becomes a pure mineral and ecological construction product, which can be easily recycled when needed. It does not harm the environment and human health.

Pricelist

ø 1 - 2 mm: 120 € / 1m³

ø 2 - 4 mm: 110 € /1m³

ø 4 - 8 mm: 95 € /1m³

ø 8 - 16 mm: 80 € /1m³

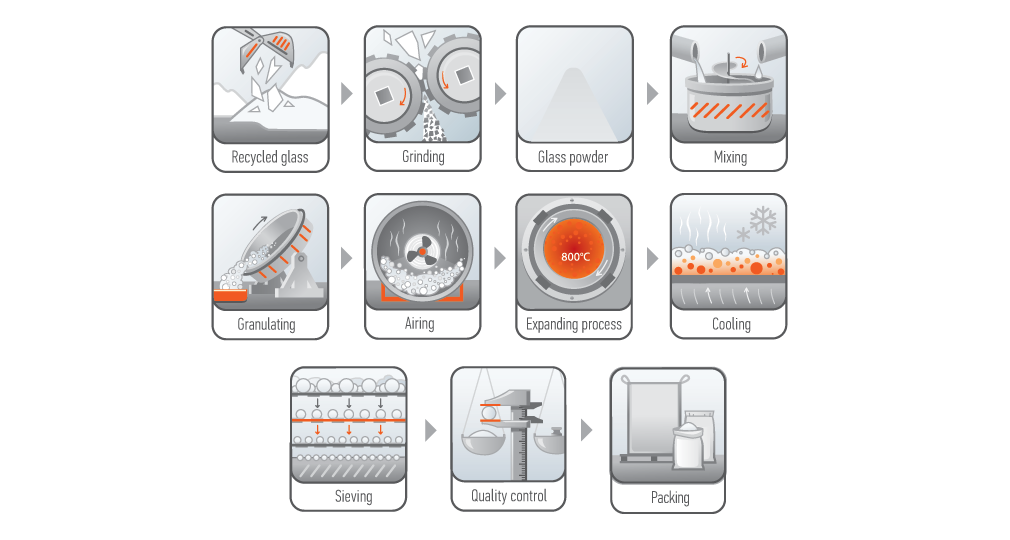

Kramer Expanded Glass Production Process

The raw material for Kramer Expanded Glass is glass or recycled glass. The pure glass constituents are ground to a fine glass powder in large mills. Then water, binding and expanding agents are added in the mixing plant.

The glass mixture is given its round shape in the granulating dish. The granulate is expanded in a rotating furnace at approx. 900°C. The

expanding process generates a fine-pored, round granulate, entrapping minute air chambers inside.

After a cooling process, the product is sieved and sorted into granular sizes,

stored in large-capacity bags and delivered to customers .

EXPANDED GLASS PRODUCTION EQUIPMENT

We also prepared upon request to supply expanded glass production equipment.

Contact Us

Find out more about Kramer expanded glass, applying or buing.

Contact us

10787, Berlin, Keithstrasse 2-4

Deutchland

Tel. +48 509 260 511 - PL